BigwigERP Inventory module

The Inventory module helps keep track of inventory based on product receipts and orders sent. It does it in real-time and offers an included feature to cross-check your warehouse and their order picking correctness.

you certain that picking and packing are accurately handled on every order?

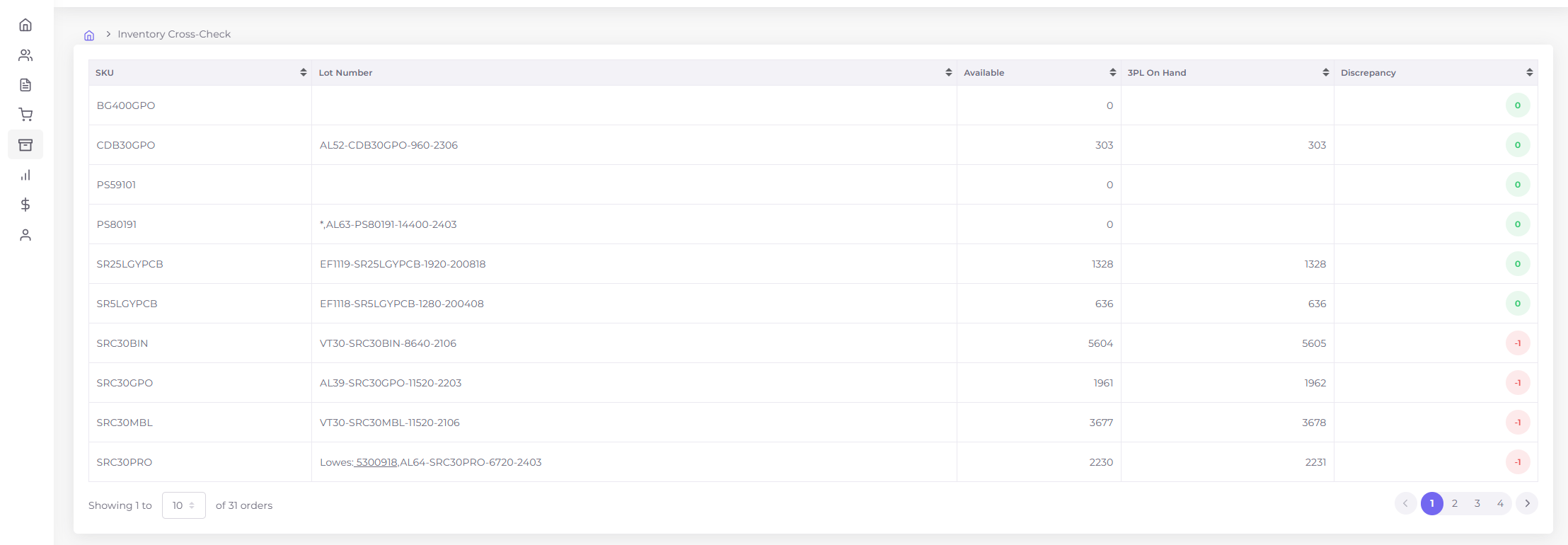

BigwigERP helps you monitor the 3PL stock and compares it with your master list for accuracy. The master list calculates product inventory allocation based on sales activity and compares it with the 3PL stock list to ensure the correct products have been picked.

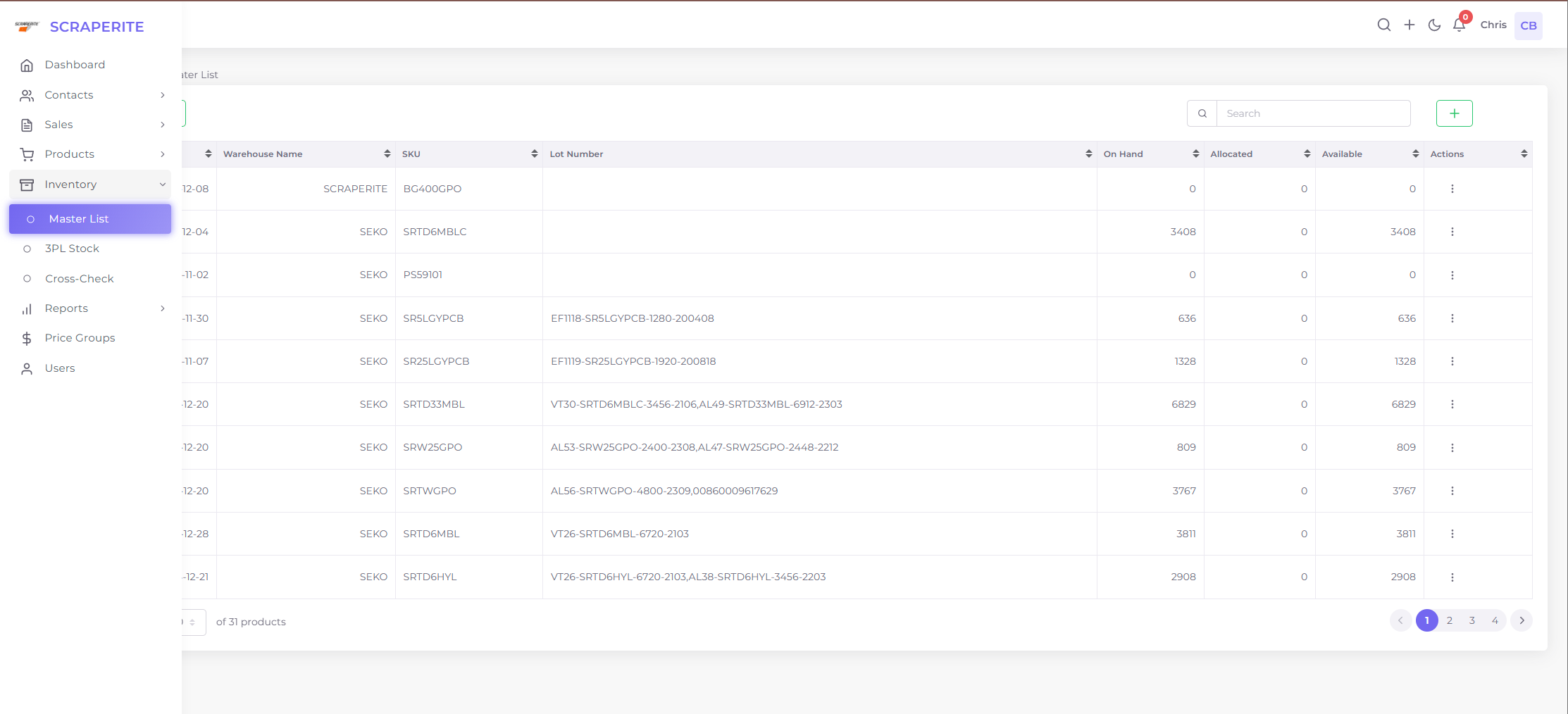

Edit and handle all the products in one place

Inventory list view

Cross-check your warehouse

It’ll make you wonder how you managed without it…

Manage inventory from one central source instead of trying to keep up with adjusting inventory numbers manually on each sales channel system. This means if you sell the same product on multiple e-commerce sites there is no need to adjust the quantities on each site separately.

The system also keeps track of multiple inventory locations. Upon receipt of a product from a purchase order placed with a vendor, inventory is booked on arrival to any tracked warehouse and added to the inventory list by date, PO number, or batch code allowing the user to later select from where the product should be pulled and shipped for outbound orders.

When orders are created the system deducts the ordered item quantity from the available inventory list and makes that amount no longer available to avoid user error of double booking. Tracking information is searched and posted daily to the customer order automatically to close out the transaction and confirm that product quantity is no longer available.

Outbound order item count can then be cross-checked electronically against the warehouse inventory numbers to verify that correct products have been sent and catch mistakes before the customer even knows something went wrong.

- Automated order entry from all your stores

- 60-second order processing

- Send sales to 3PL electronically

- manual order entry

- backorder tracking

- multiple currency handling

- invoicing

- order history views